Do geographical indications encourage local production? Analysing producers’ strategies

¿Las indicaciones geográficas fomentan la producción local? Analizando las estrategias de los productores

Revista de la Facultad de Agronomía

Universidad Nacional de La Plata, Argentina

ISSN: 1669-9513

Periodicity: Semestral

vol. 120, no. 1, 2021

Received: 06/11/2020

Accepted: 17/02/2021

Corresponding author: nilgun_stu@hotmail.com

Abstract: Providing new production alternatives in the development of the economy in rural areas of Turkey is of particular importance. Geographical indication (GI) labelling differentiates a product from its competitors as to the region where it originated. The improvement of GI labelling production strengthens the efforts of the rural regions in maintaining high standards of the product quality regarding to the health. This paper investigates the way GI is implemented by pestil (dried fruit pulp) producers in Gumushane province in Turkey. A framework formulated is urgently needed to allow the pestil producers to promote their local product to a wider market.

Keywords: GI labels, local products, rural development, Turkey.

Resumen: Proporcionar nuevas alternativas de producción en el desarrollo de la economía en las zonas rurales de Turquía es de particular importancia. El etiquetado de indicación geográfica (IG) diferencia a un producto de sus competidores en cuanto a la región donde se originó. La mejora de la producción de etiquetado de IG fortalece los esfuerzos de las regiones rurales para mantener altos estándares de calidad del producto con respecto a la salud. Este documento investiga la forma en que los productores de pestil (pulpa de frutos secos) implementan la IG en la provincia de Gumushane en Turquía. Se necesita con urgencia un marco formulado para permitir a los productores de plagas promover su producto local en un mercado más amplio.

Palabras clave: Etiquetas IG, productos locales, desarrollo rural, Turquía.

INTRODUCTION

In recent years, the notion of marketing local products has gained special importance for such reasons as consumers’ desire for fresh food, preservation of traditional foods, and supporting the local economy. Other projected advantages include shorter transportation distances, lower production costs, and the attraction for consumers of familiarity with the producer and food safety (Giovannucci et al., 2010).

Characteristic features and the quality of a product are often unique to the region where it is produced, and this uniqueness constitutes the basic incentive to use geographical signs. A geographical indication (GI) acts as a tool for the registration, promotion, and conversion of local products into tourism products (Yenipınar et al., 2014). In changing global market conditions, products with a GI label enjoy increased competitiveness, broader consumer awareness of their originality, and consumers’ confidence that they were produced with certain standards that are important for producers as well as consumers (Belletti et al. 2017). Implementing GI labelling represents an important investment in information as well as physical capital investments, which impact the dynamics of the economy in global competition. In fact, the importance of geographical indications that provide information on local products is increasing day by day in both national and international economies.

In Turkey, in areas not suitable for industrial development but open to improvement of their agricultural economy, increasing the production of local foods is a good opportunity for the local economy. It has been shown that production of local products by small businesses without the need for extensive technology is extremely effective in protecting rural areas, promoting sustainable agriculture, and responding to consumers' growing interest in healthy natural food products (Kupke & Page, 2015; Zhao et al. 2015).

Agricultural activities are among the main sources of livelihood in the province of Gümüşhane, located in north-eastern Turkey. Although the time-honoured tradition of animal production offers potential, it does not currently reach the desired level due to recent problems experienced in the sector. The geographical and climatic conditions of the province also suffer various difficulties, especially logistical, in non-agricultural investments. In the face of these problems, the production of local food specialties in Gümüşhane is seen as an advantageous alternative for mobilizing the local economy. In fact, Vorotnikov et al. (2017) emphasized that ensuring sustainability based on a balanced supply in the food market depends on increasing traditional food production in developing a regional economy. Above all, the consciousness, attitude, and behaviour of the producers must be addressed for the production of local products labelled with GI. Producer awareness plays an important role in developing GI-labelled products (Maina et al., 2018; Durand & Fournier, 2017). Menapace & Moschini (2012) showed that GI certification improves the producers’ ability to use their reputation as a means of assuring product quality.

The local product included in the scope of this research is called “pestil” (dried fruit pulp). The local description of pestil is a mixture of mulberry, honey, milk, and flour spread on cloth, and after drying, a high-nutrient fruit pulp is obtained (Gümüşhane Governorship Publications, 2010). In the past, pestil was consumed as a snack only by the local people in Gumushane province. Today it plays a vital role as an industrial product in the production sector creating added value in the province's economy and providing employment for many people. Gümüşhane produces 90% of the pestil in Turkey, and 90% of the enterprises in the industrial sector of Gümüşhane province are pestil producers, with annual production of approximately 5,000 tons.

A GI for pestil products was elaborated by the Governorship of Gümüşhane in 2004, but to date, its impact on the regional economy—particularly on local producers—has not been studied. Thus, the aim of this study is to determine whether the GI created for pestil is sufficient to encourage producers to produce their product with the GI. Undoubtedly, the number of local products with GI is steadily increasing in Turkey and around the world, but studies assessing the outcomes are almost non-existent. Such studies conducted in Turkey deal mostly with GIs’ contribution to the economy of the region and the country, their support for sustainability, and the legal procedures involved.

METHODOLOGY

Primary data in this study were obtained from Gümüşhane, the principal pestil (dried fruit pulp) production region. Face-to-face interviews were carried out to collect qualitative and quantitative primary data. Information collected from survey data covered producer demographic information, production information, geographical indication information, local market dynamics, and producer perceptions.

In accordance with the purpose of the study, a questionnaire was prepared consisting of questions for the producers of pestil in Gümüşhane province. In this study, a semi-structured interview was conducted with the producers. In this context, some of the questions were asked to the producers as five-point Likert scale and closed-ended questions. Some of the questions are structured as open-ended. Open-ended questions were asked about the cost and the price perception of the producers in GI-labelled products. Besides, there are some open-ended questions regarding the future trends of producers to produce GI-labelled products.

Thirty-two pestil enterprises recruited from the Gümüşhane Agriculture and Forestry Provincial Directorate comprised the sample. As the sample size was limited, the Full Count method was used for data collection. Each pestil producer was called to arrange an appointment for a face-to-face interview. Two producers did not agree to participate, and three businesses were found to be bankrupt. The sizes of most enterprises were similar; only one large enterprise was excluded to preserve the validity of analysis results. Surveys were conducted with the 26 selected enterprises in December 2019. Information obtained from the Gümüşhane Agriculture and Forestry Directorate, the Turkish Patent Institute database, and related literature was used as secondary data.

Data obtained from the interviewed producers are presented in simple descriptive statistics—averages and percentages. Mean scores from the 5-point Likert scale were used to report the perceptions of the producers about products with GI labelling. Correlation analysis was carried out to reveal the relationship between the price levels the producers would accept to produce their product with GI and the size of the enterprise (sales volume).

RESULTS and DISCUSSIONS

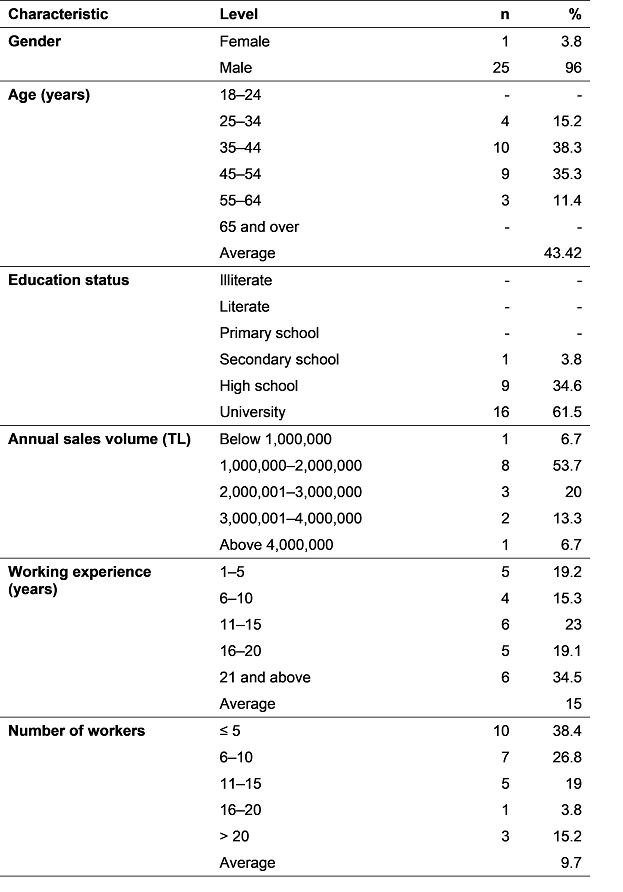

Socio-economic characteristics of the enterprises

All pestil producers in Gümüşhane were included in the scope of the research. The socio-economic characteristics of the enterprises are shown in Table 1. As the table reflects, only one of the 26 business owners participating in the survey was a woman. This result shows that the pestil production sector has become a male-dominant sector in the growth of commercial volume. Kassie et al.’s (2009) study stated that male producers, especially in developing countries, dominate the production sector, but pestil consumed in the winter in the households of Gümüşhane in past years was made by women. From this standpoint, we can say that there is an opportunity to promote women entrepreneurs in the province and further growth of the sector.

The age ranges of 35–44 and 45–54 (38.3% and 35.3%, respectively) encompass the majority of the producers. The average age was found to be 43. In considering the educational status of the participants, it was seen that the majority of participants (61.5%) graduated from college. It was mentioned in the study by Tambo & Wünscher (2017) that producers with a higher level of education are more willing to tolerate innovations such as GI that involve risk-taking actions.

On the topic of annual sales volume, the main driver of business sustainability, no response was received from 11 participants. Approximately 54% of the remaining 15 enterprises reported average annual income of 1 to 2 million TL. The average annual sales volume was found to be 2 million TL. Another factor considered significant in business success is the years of experience. The amount of experience of the producers in this study was understood to include their pestil production experience beginning even before they became official producers. The average experience of these producers was determined to be 15 years.

The size of the enterprises included in this research was classified according to work force. Enterprises employing up to five workers made up 38.4% of the total, and those employing 6–10 workers accounted for an additional 27%. Thus, it can be noted that the enterprises included in this research are small enterprises, a category known to be more flexible than large enterprises in accepting innovations, such as GI, that may positively affect production volume. As stated by Yeşil et al. (2010) in their study, enterprises must change to ensure their sustainability and reach their goals.

Production and marketing of pestil in the examined enterprises

The annual production of pestil and köme of these producers was a minimum of two tons and a maximum of 360 tons; the average amount was 96 tons. A significant part (69.2%) of the interviewed producers operate in three production branches: pestil, stuffed pestil (köme), and pestil dessert. To increase the competitive power of enterprises producing the same product, product differentiation is of special importance. According to the information obtained from these producers, the majority would like to increase their competitiveness by product differentiation.

Concerning marketing channels, 38.5% of these producers’ sales go to markets, delicatessens that sell local products, and to local or foreign traders. Second place in marketing channels is distributors with a share of 30.8%, while only a small part (7.7%) use channels such as e-commerce or direct sales to consumers. With the development of technology in recent years, marketing understanding has also changed substantially, with especially e-commerce increasing in popularity day by day. For this reason, we suggest that enterprise owners might increase their market share by considering e-commerce to use available marketing channels more effectively in changing their competitive condition.

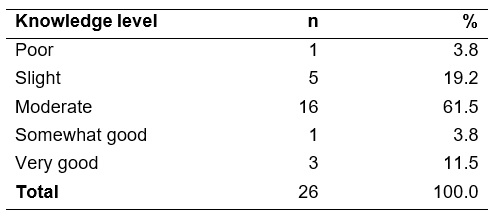

Producers’ levels of knowledge regarding geographical indicators

Approximately 62% of the interviewed producers were found to have moderate knowledge of GIs; only 4% stated that they had no information, and about 19% stated that they had very little information (Table 2).

Based on this outcome, it is clear that increasing the knowledge level of the producers may trigger more willingness to produce GI products. In the study by Lucatelli (2000) and Blakeney (2017), the level of knowledge was found to directly affect producers’ use of GIs.

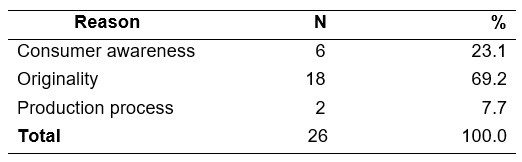

The majority (69%) of participants reported that the pestil they produce is different from that produced in other regions in Turkey in terms of the process, stating that the product has features characteristic of the region (Table 3).

Thus, we posit that the main underlying motivation for the GI registration initiated for Gumushane pestil was its originality compared to its counterparts. The distinguishing features mentioned of Gümüşhane pestil included that it is brighter and softer than others, and that it has higher nutritional value due to the honey, milk, and a greater amount of walnuts or other nuts in its ingredients. In recent years, the demand for local products has been increasing all over the world. It was reported in the study published by Maina & Mburu (2016) that producers in Europe, South America, and Asia have increased their efforts in recent years to protect the products characteristic of specific regions in the market.

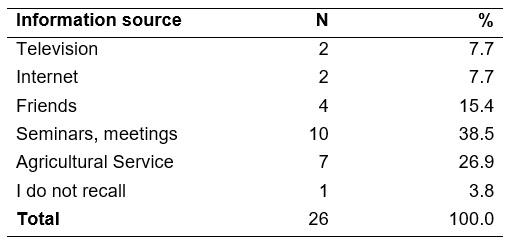

Producers’ sources of information on GI

When information sources were examined, it was seen that 65.4% got their information from special seminars, meetings, or from the agricultural service, and 15.4% had obtained it from friends (Table 4).

How producers obtain information is as important as the level of knowledge they have. Asymmetric information shared among the producers may emerge as a factor negatively affecting the possibility of using a GI label. Training and awareness-raising activities can prevent asymmetric information and be effective in promoting production using GI. A similar conclusion was found in a study by Tey et al. (2014) that stated that it is more important to implement information-based innovations rather than technology-based investments to ensure the sustainability of small businesses.

Perceptions of the potential benefits of production with GI labels

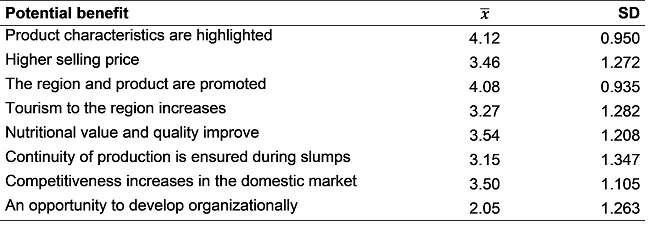

For participants producing pestil (dried fruit pulp) or köme (stuffed fruit pulp) with GI labelling, a 5-point Likert scale was used to measure their perceptions of the benefits to be realized. According to results, the characteristic features of the product will be distinguished as to region, and the pestil or köme will be promoted more effectively. The participants significantly agreed with these propositions. On the other hand, they were undecided about the ideas that “pestil would be sold at a higher price if it was produced with GI label” and that “continuity of production would be ensured during sales slumps”. Producers significantly agreed that production with GI under current market conditions will increase the competitiveness of the product, but they were not convinced that producing with a GI label would provide greater opportunity for producers to organize (Table 5).

Willingness of producers to use GI

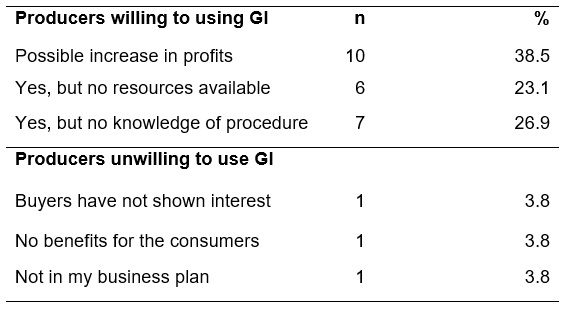

The principal research question was to determine why the GI registration certificate obtained by the Gümüşhane Governorship in 2004 was not being used. In this section, closed and open-ended questions were asked to measure the participants’ reasons for not using GI. Approximately 89% of the respondents said “yes” to using the GI label on their products, and 12% said “no” (Table 6). Of those saying “yes”, 38.5% affirmed that they are financially ready and believe that this innovation will increase their profits, and 27% stated that they wanted to use the GI label but did not know how to proceed. Another 23.1% said they were willing but lacked sufficient resources. Among those unwilling to use the GI label on their product (11.5%), 7.6% stated that buyers and consumers had not requested it; they indicated that they do have adequate resources but are unwilling to contemplate increased production costs. The remaining respondent (3.8%) said simply that such an innovation is not part of their business plan (Table 6).

These producers pointed out the risk of a serious impact on sales because they do not believe the benefits of GI labelling will be important in the eyes of the consumer. Researching the consumer dimension at the point of sales in the next phase of this research will yield important feedback for the current producers (Sitepu, 2018).

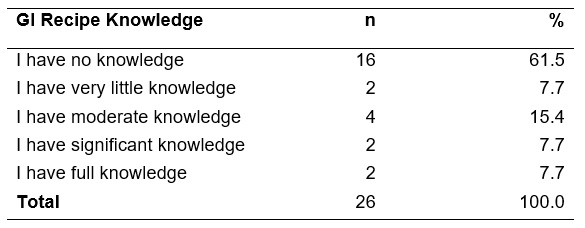

Extent of producers’ knowledge of the GI recipe

Business profits are the most effective motivation for seeking growth and innovation. Undoubtedly, producers must know their production costs in order to consider taking steps towards producing GI-labelled pestil and köme. In light of the educational status of the surveyed participants, it is clear that they are capable of making forward-looking decisions based on their business plans like innovation. The survey results demonstrate that, despite the social and cultural benefits of producing GI products, the main concern of the producers is economic. Before making cost comparisons, the participants were asked whether they knew the recipe for preparing GI-labelled pestil and köme. Approximately 62% of the participants had no knowledge of the quantities of ingredients used to produce pestil or köme for the GI label, and 7.7% more reported having very little knowledge. Those with moderate knowledge were 15.4% of respondents (Table 7).

In face-to-face interviews, the chief concern of those with no knowledge was production costs. Participants said that the recipe of Gümüşhane pestil made in the traditional method is not possible under current market conditions. The components used in their present production are not the same as those used in the product with GI. Most importantly, the recipe from the Gümüşhane Agriculture and Forestry Provincial Directorate consisted of very different input quantities. It calls for at least 20 kg of honey, 15 kg of milk, and 20 kg of walnuts or hazelnuts for 100 kg of Gümüşhane pestil, and the milk and mulberry must be from Gümüşhane. For industrial production, the syrup that extends shelf life used in current production is not allowed in production with GI.

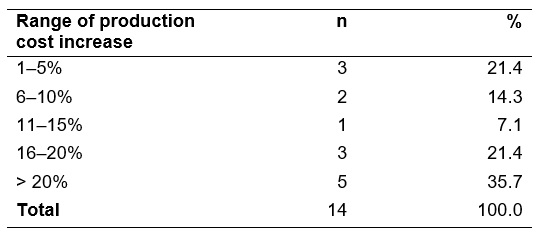

Participants were then asked whether producing GI pestil will increase production costs. Approximately 54% of the participants answered in the affirmative, while 34.6% stated they were uncertain, and 11.5% did not know. Aligning the cost estimates with knowledge of the recipe returned the expected findings: of those who answered “yes” to the knowledge question, 35.7% stated that production costs would increase more than 20%; 21.4% of the producers said the increase would be in the range of 16%–20%, and the other 21.4% set the range at 1%–5% (Table 8).

The answer to our basic research question—why current production is not using GI labelling—has been partially explained by these findings.

Producers’ opinions and the expected price for sales of GI production

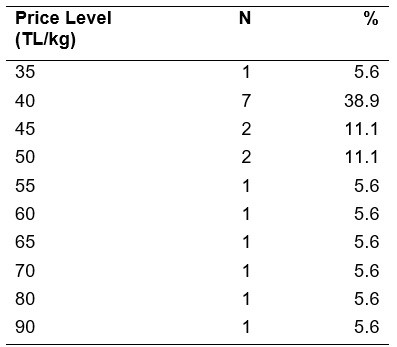

To further examine the willingness of producers to sell GI-labelled products, they were asked about likely price differences between the GI product and non-GI product. While 69.2% of the participants answered “yes”, 3.8% answered “no”, and approximately 27% answered “I don’t know”. Eighteen participants responded to the question, “At what price would you consider selling products with GI label?” The remaining eight participants could not make price estimates. Table 9 below shows the price level at which producers said they would produce GI-labelled products. The greatest number (38.9%) accepted 40 TL ($6.94) as the production price per kg.

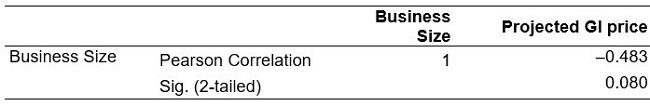

Correlation analysis was carried out to reveal the relationship between the acceptable price levels for producing their product with GI label and the size of the enterprise (sales volume). The analysis showed a weak and negative relationship (r = –0.483, p = 0.08) between the size of the enterprise and the price level accepted (Table 10).

Although the relationship is weak, this result reveals that, as the size of the business increases, the price level that manufacturers would accept to produce GI-labelled products decreases.

Comparative analysis of costs in traditional versus GI production conditions

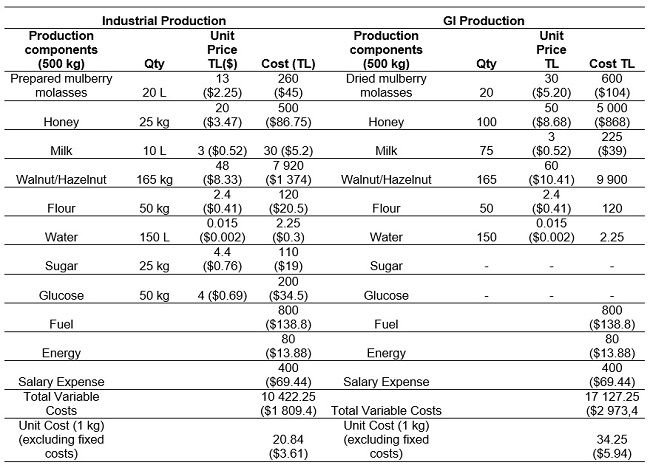

According to the pestil production cost information gathered, business owners use basically the same ingredients, although the amounts of each may vary from one to another. Table 11 presents the production costs resulting from using the input amounts in the GI registration certificate (2004) obtained from the Directorate of Agriculture and Forestry of Gümüşhane Province and the current production costs in industrial conditions.

As it was found Tambo et al. (2020)’s research, one of the main reasons for the producers for GI labelled production falls under money expended in the innovation process.

Comparing the two, we see that the ingredients used are basically the same, but the amounts in the GI registration of 2004 have not been revised in keeping with present market conditions. The unit costs obtained explain in general terms why the producers do not wish to produce with GI under current market conditions. Looking at the inputs individually, it can be seen that the high ingredient amounts required of honey and milk significantly increase costs. The price of these ingredients is quite high in the current market. Thus, producing GI-labelled products adhering to the required amounts is unreasonable. In addition, strategies such as using glucose syrup to increase product shelf life and making substitutions to lower costs are not allowed in GI production. As shown in Table 11, producing GI-labelled pestil is approximately 62% more costly per kg than industrial production of non-GI pestil. It is clear that the recipe created in 2004, similar to the traditional pestil in terms of its naturalness, is not suitable for industrial production of pestil, which has become a viable industrialized sector today. In light of this comparison of production costs, we hope that these findings will serve as a guide for both producers and public authorities or associations. The input amounts for honey, milk, and walnuts or hazelnuts required to yield of GI product increase the production costs beyond what current market conditions can readily absorb. According to the producers interviewed, milk is the ingredient that causes the product to deteriorate quickly, thus shortening the product’s shelf life, and is not essential for its flavour. A similar case can be made for honey. Although the price of honey varies widely in the current market (from 10 TL/Kg ($1.73) to 100 TL ($17.36) TL/kg), it is used only to add taste to the product. Implementing production with a CI label involves adherence to an established standard for the quantity and quality of the honey; the flexibility of adjusting input amounts seasonally to reduce costs is no longer available.

The production of GI-labelled products may cause an increase in costs. The fact that the inputs used in the production of GI-labelled are of high quality and generally obtained from the region can increase the cost. This is also the same case for the pestil produced in the Gümüşhane region. As a matter of fact, basic inputs such as honey, milk and walnut (or hazelnut) must be obtained from the region for the production of an original GI-labelled pestil. This normally increases the cost of the production. However, it will not be right to focus on cost in GI-labelled products such as pestil. Since GI-labelled products are included in the sustainable product group, it should be seen as normal that the cost of such products and therefore the product sales prices are high. It is clear that GI-labelled products have an advantage in the market in terms of promotion compared to industrial products. For this purpose, producers should establish a strong promotion strategy while marketing their products.

CONCLUSION

This study was carried out to determine why pestil and kome producers in Gümüşhane province do not produce GI-labelled products. It was determined that the registration certificate obtained in 2004 for Gümüşhane pestil was not used by any producer in the current production market. No research has been found to examine the social, economic, environmental, or consumer aspects of producing GI-labelled products in Turkey. Nonetheless, it is obvious that production of GI-labelled pestil would provide many benefits for both producers and consumers while enhancing its social, cultural, and environmental attributes (Neilson et al. 2018).

According to the analysis results obtained from this research, there are six dimensional factors that summarize the producers’ perceptions about the role of geographical indications in pestil production. We can summarize these factors as adherence to the current market, input supply, and policies on GI, ingredient prices, knowledge, and stakeholder engagement.

The information obtained from the producers in face-to-face interviews points to the impracticality of manufacturing pestil in accordance with the recipe established in the registration document formulated in 2004 on the basis of naturalness and originality and aiming to replicate household pestil-making in older times. The required ingredients and their quantities did not include substances added in industrial production to ensure shelf life and softness of the pestil, which transformed the typical household production into industrial production over time. It is expected that the formulation of a renewed recipe will be an important step for manufacturers to become interested in producing a product with a GI label. Towards this end, the actions of both local authorities and unions will be indispensable.

As revealed in the findings of this research, pestil business owners are aware of the distinctive features of the pestil they produce compared to that produced under different product names in other provinces, but knowing the distinctive features is not enough to implement GI labelling for their product in the current market (Giovannucci et al. 2010; Maina et al. 2018). Exploring the level of knowledge of GI of the producers participating in the survey and their willingness to use the GI label demonstrated that the biggest obstacle for these provincial producers to produce GI-labelled products is the input amounts in the recipe.

We submit that the producers who do not have information about GI labelling can also be potential producers by supplying them more information and training. Of course, the production of GI-labelled pestil will only be achieved if it generates sufficient interest among producers. In this regard, disseminating the levels of cost and price data as calculated here in may foster further interest in producing GI-labelled products. The extent of the impact on industrial pestil production costs from converting to GI production will serve as a guide for local authorities and producers.

BIBLIOGRAFY

Belletti, G., A. Marescotti & J.M. Touzard. 2017. Geographical indications, public goods, and sustainable development: The roles of actors’ strategies and public policies. World Development 98: 45-57.

Blakeney, M. 2017. Geographical indications and environmental protection. Frontiers of Law in China. 12(2): 162-173.

BÜMKO. 2018. Average Exchange Rates. Ministry of Treasury and Finance of The Republic of Turkey, http://www.bumko.gov.tr/TR,147/ekonomik-gostergeler.html [Accessed June 10, 2020]

Durand, C., & S. Fournier. 2017. Can geographical indications modernize Indonesian and Vietnamese agriculture? Analyzing the role of national and local governments and producers’ strategies. World Development 98: 93-104.

Giovannucci, D., E. Barham & R. Pirog. 2010. Defining and marketing “local” foods: Geographical indications for US products. The Journal of World Intellectual Property 13: 94-120.

Gümüşhane Governorship Publications. 2010. Manufacture of pestil (Fruit Pulp), Gümüşhane.

Kassie, M., P. Zikhali, M. Kebede & S. Edwards. 2009. Adoption of sustainable agriculture practices: Evidence from a semi-arid region of Ethiopia. Natural Resources Forum 33: 189-198.

Kupke, V. & G. Page. 2015. Does the farmer want a market? Factors impacting on participation by local producers in farmers markets. Pacific Rim Property Research 21: 61-75.

Lucatelli, S. 2000. Appellations of origin and geographical indications in OECD member countries: Economic and legal implications. OECD. Paris, France. 73 pp.

Maina, F.W., & J. Mburu. 2016. Assessing producers’ perceptions of protecting coffee and apple mangoes as geographical indications in Kenya. 23-26 September, 5th International Conference of AAAE, Ethiopia.

Maina, FW., C. Ackello-Ogutu, J. Mburu & H. Egelyng. 2018. Producers’ perception of geographical indications as a product diversification tool for agrifood products in semi-arid regions of Kenya. International Journal of Food and Agricultural Economics 6(2): 85-100.

Menepace, L. & G. Moschini. 2012. Quality certification by geographical indications, trademarks and firm reputatıon. European Review of Agricultural Economics 39: 539-566.

Neilson, J., J. Wright & L. Aklimawati. 2018. Geographical indications and value capture in the Indonesia coffee sector. Journal of Rural Studies 59: 35-48.

Sitepu, F.Y. 2018. The potential of Geographical Indications and its legal protection. Web of Conferences 52(17): 1-6.

Tambo, J.A. & T. Wünscher. 2017. Enhancing resilience to climate shocks through farmer innovation: evidence from northern Ghana. Regional Environmental Change 17: 1505–1514.

Tambo, J.A., E. Barake, A. Kouevi & G.T. Munthali. 2020. Copyright or copyleft: An assessment of farmer-innovators’ attitudes towards intellectual property rights. Journal of Rural Studies 74: 133-141.

Tey, Y.S., E. Li, J. Bruwer, A.M. Abdullah, M. Brindal, A. Radam, M.M. Ismail & S. Darham. 2014. The Relative importance of factors influencing the adoption of sustainable agricultural practises: a factor approach for Malaysian vegetable farmers. Sustainability Science 9: 17-29.

Vorotnikov, I., I. Sukhanova, L. Tretyak & S. Baskakov. 2017. A Logistic model of sustainable food supply of the region. Productive Forces Development and Regional Economy 164: 94-98.

Yenipınar, U., H. Köşker & S. Karacaoğlu. 2014. The importance of local food and Geographical Indications in tourism: Van Herb Cheese. Journal of Tourism and Gastronomy Studies 2: 13-23.

Yeşil, S., Ö. Çınar & E. Uzun. 2010. A field study on innovation activities of businesses operating in KahramanMaraş. The Journal of Knowledge Economy & Knowledge Management 5: 81-99.

Zhao, X., M. Kneafsey & D. Finlay. 2015. Food safety and Chinese Geographical Indications. British Food Journal 118: 217-230.

Author notes

nilgun_stu@hotmail.com